WASHINGTON, D.C. — A new metal alloy, specifically engineered at the atomic scale, is challenging the long-held principle that ordinary metals become brittle and fracture in extreme cold. Researchers have created a cobalt-nickel-vanadium alloy that maintains its strength and toughness even at a chilling -186°C, a temperature that would render most conventional metals highly fragile. This discovery holds significant promise for a variety of industries, from space exploration to clean energy.

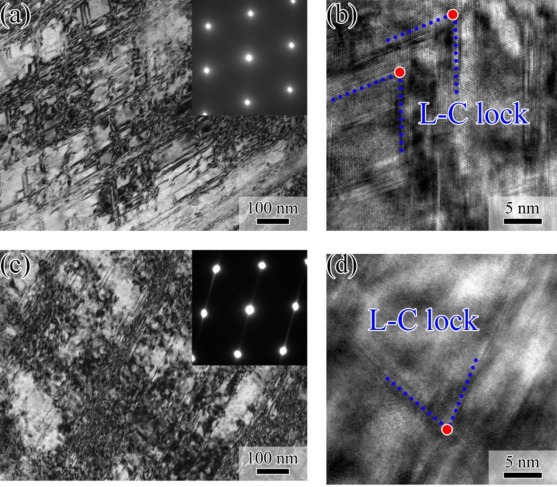

The findings, published in the journal Nature, reveal that the material’s remarkable properties are due to a “dual-ordered” atomic architecture. Through a precise process of heating and shaping, the scientists were able to manipulate the alloy’s atoms into two distinct patterns: sub-nanoscale islands of a “short-range order” and larger “nanoscale domains of a long-range order.” This unique self-assembly of atoms is what sets the new alloy apart.

This atomic structure is engineered to impede the growth of cracks, keeping the metal ductile and preventing it from becoming brittle as the temperature drops. In tensile tests conducted at -186°C, the alloy not only remained exceptionally strong but also absorbed significantly more strain before fracturing than normal metals. The research demonstrates that this type of precise, atomic-level design can give materials unprecedented toughness in cold conditions.

The potential applications for this cold-resistant alloy are numerous and diverse. Its ability to endure intense cold makes it an ideal candidate for spacecraft components that must operate in the unforgiving environment of deep space. Furthermore, it could be used to fortify cryogenic fuel infrastructure, such as pipelines and tanks designed to store liquefied natural gas (LNG), hydrogen, or oxygen, where the integrity of the materials is critical for safety and efficiency.

According to the research team, this groundbreaking atomic-level approach could be applied to other metal systems, potentially leading to the development of a new generation of materials that are resilient in the most extreme cold.